I recently started getting back into cycling and was poking around the bike market to see how things were looking, potentially to replace my old 2013 Cannondale Synapse. It’s still a very nice bike but bike tech has come a long way in the last 10 years, especially with carbon fiber.

Carbon bikes have come down a huge amount in price, however, the pandemic seems to have spiked them back up. I came across a Reddit post about building a bike using carbon frames directly from Chinese manufacturers. After reading some of the forums dedicated to this, primarily chinertown, it seemed like it would be worth a shot. If I could price out a build cheaper than the cheapest decent full carbon bike I could find, the Canyon Endurace CF 7, I’d go for it.

So I started pricing a build-out:

| Component | Part | Price |

|---|---|---|

| Frame | Carbonda CFR1056 | $650 |

| Handle Bars | Carbonda CHB1036 | $0 (included with frame) |

| Axles | Carbonda aluminum axles | $26 |

| Group set | Sensah Empire Pro | $383 |

| Brakes | Juintech F1 | $136 |

| Wheels | Elite Wheels 50D | $1011 |

| Tires | Continental Grand Prix 5000 | $104 |

| Tubes | Continental tubes | $19 |

| Saddle | Specialized Power Comp | $100 |

| Cables | Jagwire brake/shift kit | $65 |

| Total | $2494 |

Came out pretty close in price, however with a much nicer carbon wheelset.

Frame

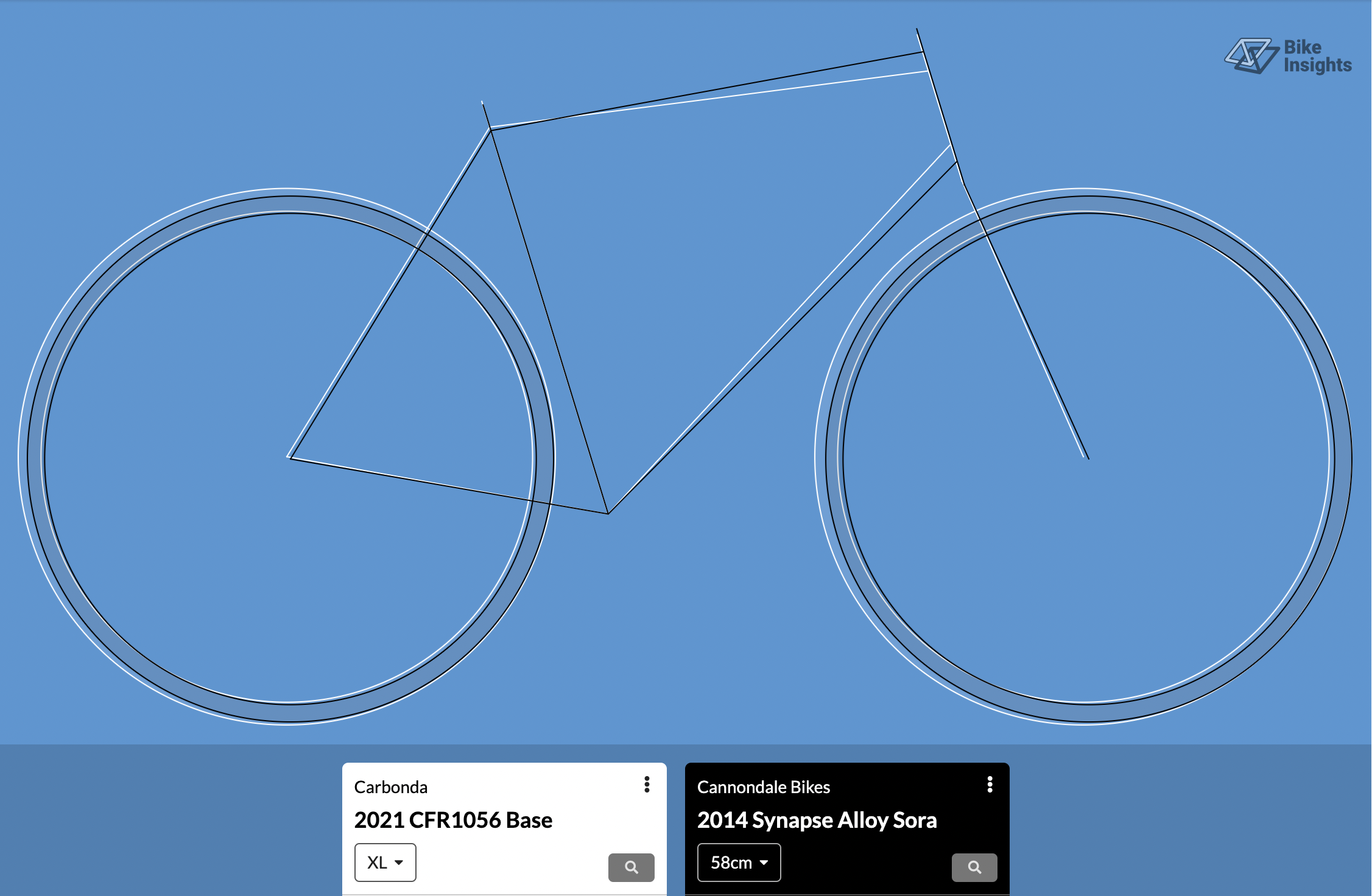

I was looking for a frame that was similar in geometry to my Synapse and found the Carbona CFR1056 seemed to fit the bill. It had pretty good reviews from the guys on chinertown and the builds all looked pretty sharp. Plus the geometry was almost identical to my Synapse.

You can’t order directly from Carbonda’s site but I emailed their sales team and they got back to me pretty quickly. The ordering process overall was pretty painless, you can tell they are still in the early stages of dealing with consumers directly as it was still very b2b feeling with invoices and the like. The worst part was dealing with UPS, my town is now considered a remote area, as is my brother’s, so I had to send it to my brother-in-law’s house to avoid an additional $50 remote area charge.

The frame included a pretty nice aero-style flat handlebar, they did charge a little for some decent anodized aluminum axles and an extra rear derailleur hanger. I paid via PayPal and the frame came about 6 weeks later, it was delayed a few weeks due to the Chinese new year.

Overall the bike and handlebars are really nicely constructed, carbon layup from looking internally with a bore scope looked great. Paint was pretty nice with no major imperfections and held up to overseas shipping. Machining and threaded inserts were decent, the bottom bracket threads (BSA) were a little rough but I had no issues threading in the bottom bracket. The manufacturer ran plastic tubing through the frame for the front and rear derailleur cables and for the rear brake, that exited through a cover on top of the down tube. That was a nice touch that saved me quite a bit of time when routing the cables.

Group Set

I saw quite a few good reviews about the Sensah Empire Pro group set. It’s a 12-speed with carbon shift paddles and a carbon rear derailleur hanger. From what I’ve read it seems to be a SRAM clone, allegedly Sensah is made up of ex-SRAM engineers, the shifters at least shift SRAM style. Indexing and fine-tuning the rear derailleur was fairly painless, the shifts are crisp and quick, with no hesitation across the 12 cogs. My only gripe with the rear is figuring out which limit screw adjusts the high/low and B-gap limits since they weren’t labeled. The front derailleur is pretty standard and shifts as you’d expect, and it comes with 4 trim positions which is pretty nice. The group set came with a pair of garbage unbranded brake calipers. After looking around some more on Aliexpress it seems you can get the groupset a little cheaper if you opt for the bundle without the brakes.

The front chainring is a Senicx PR3 which came bundled with the group set. It seems decently built, appears to be mostly aluminum and the machining and tolerances on it are not bad at all. I may end up replacing it with a chainring that is compatible with a “spider” type power meter in the future.

Brakes

Likewise, with the group set, I saw a lot of discussion around Juintech brakes. They seem to be the leader in Chinese designed and built bike brake calipers. The most common calipers I saw discussed were the R1, F1, and GT-F. The main differences between them are, the R1 is the lightest, the F1 is the “standard” tier, and the GT-F is a 4-piston version of the R1. I opted to go with the cheapest of the bunch, the F1’s. The interesting bit about these calipers is they are cable actuated hydraulic brakes. Your standard brake cable attaches to a piston on the caliper which is filled with mineral oil that acts on the pistons. It’s a pretty clever way to get hydraulic braking force out of a non-hydraulic group set. Allegedly the brake feel is not quite as good as a true full hydraulic braking system but that’s fine with me coming from rim brakes.

Wheels

I spent the most time deciding which wheelset to get for this bike. The biggest was finding wheels that support a 12-speed cassette. 12-speed cassettes have an additional cog set behind where most cassettes end, this overhangs a bit into the hubs and potentially into the spokes. Some 11-speed wheels technically, but not officially, support 12-speed cassettes. I didn’t want to deal with shipping a non-functional wheelset back to china, most likely on my dime, so I opted for some wheels that were slightly more expensive than I was shooting for. The wheels I looked into were, the Winspace Lun Hyper, both the 2020 and 2023 models, the ICAN Aero 50’s, and finally the Elitewheels Drive 50. They all reviewed quite well, however, the Elitewheels Drive was the only set to officially support 12 speeds.

The wheelset is exceptionally nice, and the finish on it is very glossy which allows you to see the carbon layup on it, it’s a very interesting look almost akin to marble. The rim and spokes are entirely carbon making it very light but quite stiff, the wheel runs extremely true, I wasn’t able to detect any run out on the wheels at all. My only complaint, which I think I can fix, is the freehub is very very loud. I would’ve preferred a quiet if not silent freehub, but in biking it seems louder == better. The wheels come with ceramic bearings which are a hot topic in the bike industry currently. I would’ve gone with regular high quality steel bearings, but we’ll see how long these hold up. I was able to use a discount code I found from a youtube review to knock ~10% off the price.

As for tires, I’m running Continental Grand Prix 5000s. They seemed to have decent reviews and scored well with low rolling resistance with decent puncture resistance from tests done at bicyclerollingresistance.com, and not being terribly expensive.

The wheels are intended for centerlock brakes, however, I got some cheap 6 bolt to center look adapters off amazon since the brake calipers and groupset came with 160mm rotors.

The Build

The building process was quite frustrating at times. Initially, I was going to go full hidden, internal cable routing since the handlebars supported it. However, that turned out to be a bad idea. In order to get the cables down the head post they had to make a very sharp 90° bend in the handlebars. This permanently creased the cable housings and made braking and shifting sluggish and unresponsive. Plus, routing the extremely stiff cables internally through rough scratchy carbon handlebars was an enormous pain and time sink. After figuring out that was not going to work I yanked everything out and routed the cables semi-internally. There is a small opening in the top of the down tube, and along the side of the head post for routing cables in. That went pretty smoothly and the shift/brake feel is much better.

During the build process, I did need some special tools to complete it. I needed a 16-notch bottom bracket socket for both the bottom bracket and the brake rotor locknut. As well as a cassette lockring tool. I didn’t particularly want to pay money for some tools I’d use only potentially a couple of times, so I decided to see if I could 3D print them. Both tools needed to hit a torque of around 40nm (~30ft-lbs), which is quite high for things like this with fairly small engagement surfaces. I managed to find some models of the tools I needed online and after making some slight modifications, printed them out. They both worked surprisingly well and I was able to hit the torque specs needed without much trouble. The tools are a little beat up now however, so if I needed to do some more work I’d more than likely need to run off some replacements.

An interesting thing I learned with carbon framed bikes, is the need to cut the fork stem. The stem comes about 3 inches longer than needed with the intention that you trim it down to the desired height once you get your handlebar spacers in place. I was able to cut it fairly easily with a regular hacksaw blade, I should’ve however wet the surface down a bit as the carbon fiber is much dustier than I anticipated, and carbon fiber dust is not particularly good for your lungs.

It’s still a little too cold here in Iowa to ride it yet, but I’ve thrown in on my trainer to get it roughly fitted to me. Overall, I’m pretty pleased with how it turned out at the moment. I’m sure some things will come up on the shakedown ride, I’ll probably make some additional posts here after I’ve got some time in the saddle with it. The finished weight comes out to around 17.3 lbs according to my bathroom scale, not bad. Would I build another bike? Probably, we’ll see how this Chinese drivetrain and frame hold up. At the time of writing this, I’ve already seen L-Twoo (another Chinese groupset manufacturer) produce an electronic groupset that looks like it’ll give Shimano/SRAM a run for their money.